In today’s competitive packaging landscape, flexible packaging has gained immense popularity due to its versatility, lightweight nature, and ability to preserve product freshness. Central to the effectiveness of flexible packaging is the role of lamination adhesives. These adhesives provide crucial bonding between layers, ensuring that packages perform optimally while maintaining aesthetic appeal. This article explores the importance of lamination adhesives in flexible packaging and their impact on various aspects of product delivery.

1. Enhanced Barrier Protection

One of the primary functions of lamination adhesives is to create a barrier against environmental factors such as moisture, oxygen, and light. These barriers are essential for:

Extending Shelf Life: By protecting contents from degradation, lamination adhesives help extend the shelf life of perishable goods, making them suitable for longer distribution channels.

Preserving Flavor and Freshness: In food packaging, preventing moisture ingress is vital for retaining flavor and texture. Effective laminates ensure that snacks, sauces, and other food items maintain their quality until consumption.

2. Durability and Strength

Flexible packaging must endure various physical stresses during production, transportation, and handling. The use of high-quality lamination adhesives contributes to:

Structural Integrity: Strong bonds formed by lamination adhesives prevent delamination, ensuring that multi-layer structures remain intact.

Resistance to Damage: Laminated packages are typically more resistant to punctures and tears, providing better protection for the contents inside.

3. Aesthetic Appeal and Branding

In a market saturated with choices, the visual appeal of packaging plays a significant role in consumer decision-making. Lamination adhesives facilitate:

High-Quality Printing: They enhance print adhesion on the package’s surface, allowing brands to showcase vibrant graphics and logos that attract consumers.

Surface Finish Options: Lamination can create various finishes—glossy, matte, or textured—that enhance the tactile experience and overall appearance of the product.

4. Versatility in Applications

Lamination adhesives are applicable across a wide range of industries. Their adaptability allows for:

Diverse Substrate Compatibility: Whether bonding films, papers, or foils, lamination adhesives can cater to various substrate materials, serving different needs within sectors like food, pharmaceuticals, and consumer goods.

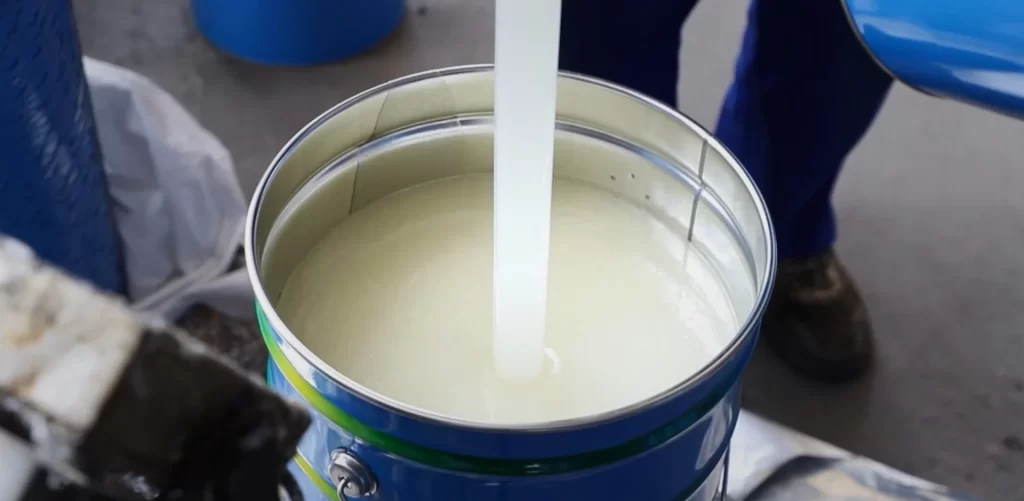

Customizable Formulations: Different types of adhesives (water-based, solvent-based, hot melt, and UV-curable) allow manufacturers to select the best option based on specific performance requirements.

5. Cost-Effectiveness

Investing in lamination adhesives can lead to substantial cost savings for manufacturers and retailers. Benefits include:

Reduction in Waste: By extending product shelf life and improving durability, there is less spoilage, leading to decreased waste in the supply chain.

Efficiency in Production: High-performance adhesives can streamline manufacturing processes, reducing the time and resources needed for packaging operations.

6. Environmental Considerations

As sustainability becomes increasingly important in packaging, lamination adhesives have evolved to include eco-friendly options. This shift supports:

Lower VOC Emissions: Water-based and bio-based adhesives reduce harmful emissions, contributing to greener manufacturing practices.

Recyclability of Packages: Innovative adhesive formulations can improve the recyclability of laminated packages, aligning with global sustainability goals.

Conclusion

The importance of lamination adhesives in flexible packaging cannot be overstated. They serve as the backbone of modern packaging solutions, enhancing barrier properties, durability, aesthetics, and cost-effectiveness. As brands continue to embrace flexible packaging, understanding the role of lamination adhesives will be crucial for delivering high-quality products that meet consumer expectations while supporting sustainability efforts