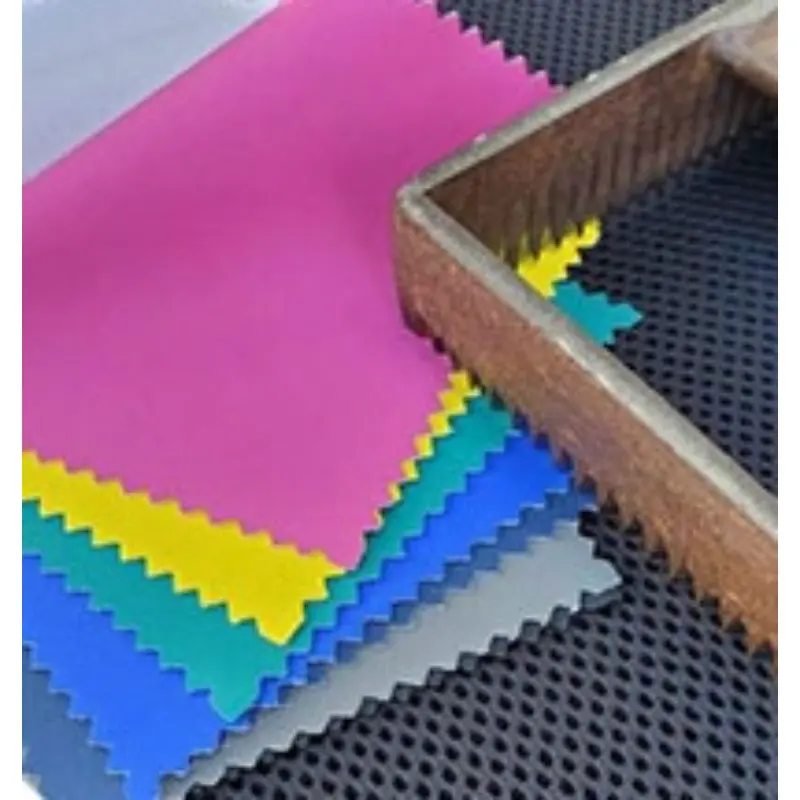

PUR4100 adhesive for cloth-on-cloth and cloth-on-film

PUR reactive adhesive;

cloth-cloth laminating adhesive;

cloth-film laminating adhesive

This adhesive has excellent initial adhesion and can be quickly attached to various surfaces in a short time, providing a good initial bonding effect.

At the same time, its bonding strength is excellent after curing, which can ensure long-term strong bonding and adapt to a variety of complex application environments.

After curing, the material's high temperature resistance is particularly outstanding, and it can work stably for a long time under high temperature conditions and maintain a good bonding effect.

- description

- Details

-

-

1. product data

parameter single component solid content(%) 100 viscosity(cps/90℃) 8000±2000 density(g/ml.85℃) 1.2 smell No smell appearance Viscous liquid 2. recommended procedure

- open time: More than five minutes

- Coating temperature: 90-110 °C

- Melt temperature: 100-120 °C

- Coating method: Roller coating

- Glue amount: Depends on application conditions. The general coating amount is 8-20g/㎡.

- Preprocessing:The substrate needs to be clean, dry and free of grease. For low surface energy substrates, corona or flame treatment is required.

- Preparation before gluing: Please prepare the glue melter, heating plate, feed pump and discharge gun, and set the appropriate temperature. Excessive heating will cause the adhesive to decompose. It is recommended to use it below 130 degrees. Users who use adhesive melt tanks must use nitrogen for protection. The humidity of nitrogen must be below 5ppm, otherwise it will accelerate the formation of skin. After opening the package, please use it up as soon as possible.

- Curing conditions: In order to achieve complete curing, the composite product should be stored at a suitable temperature and humidity (e.g. 25°C and 50% RH, or above). Under suitable conditions, curing will be completed within 7 days. At lower temperatures and humidity, it will take longer to achieve complete curing.

3. Storage & safety

- In a dry and clean environment at 5-30℃, the shelf life of the unopened product in the original packaging is ≤9 months. The opened but unused product should be used up as soon as possible.

- Be careful! Empty adhesive drums also contain hazardous materials. Please follow the instructions on the adhesive drums and do not use the empty drum without professional cleaning.

4. Packing Info.

- 20kg/drum or 200kg/drum

5. Cautions

- During use, please adjust the temperature according to the ambient temperature, machine speed, glue application amount, fabric density (glue consumption), etc. to ensure the composite effect.

- Due to the diversity of substrate types and surface treatment conditions of each user, the equipment process conditions will vary. It is recommended that each user conduct tests first.

- Ambient humidity has a significant impact on the composite effect, and the ambient humidity should be kept relatively stable during use. If the relative humidity is lower than 30%, humidification is required.

- To ensure the composite effect, the substrate to be composited must reach a certain dyne value before it can be composited, and it is recommended to be greater than 36mN/m.

- If the equipment is stopped (more than 60 minutes), the adhesive system should be thoroughly cleaned with a solvent/plasticizer mixture or other cleaning agent before the adhesive becomes insoluble (pay attention to safety)

Product Categories

hot products