The solvent-based two-component polyurethane adhesive is ideal for laminating various substrates including thermal insulation materials, air duct materials, and cable membrances. It is designed to perform efficiently across a range of speeds in dry laminating machines, ensuring strong and durable bonds in industrial applications.

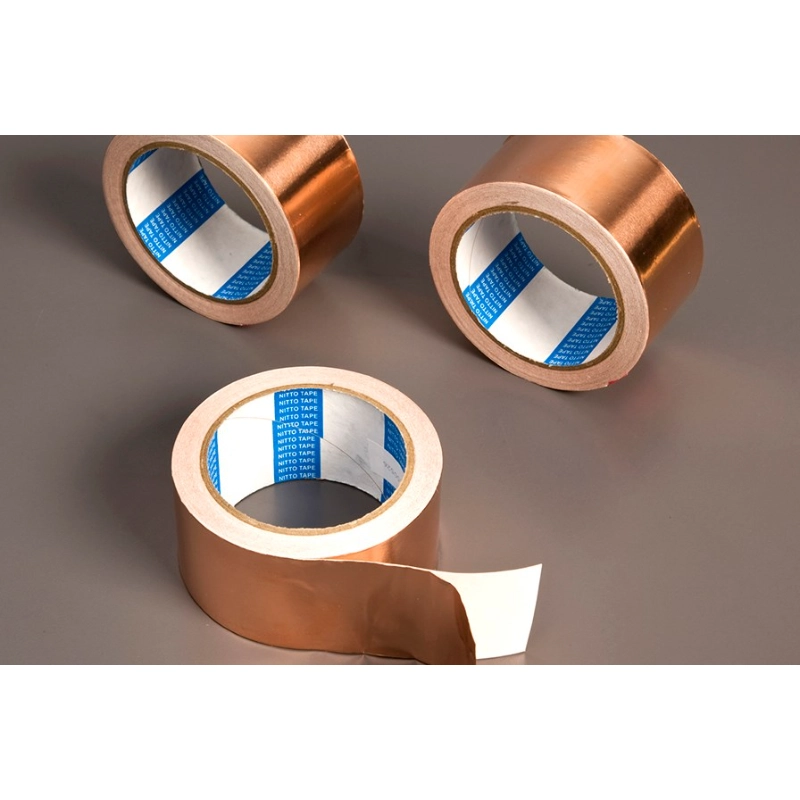

Aluminum-plastic and copper-plastic lamination adhesive JT1150/GT1150

This solvent-based two-component polyurethane adhesive offers outstanding initial adhesion, along with impressive chemical resistance, heat resistance, and coating performance.

It excels particularly in bonding aluminum-plastic and copper-plastic composites, providing exceptional strength and flexibility for durable laminates in various industrial and construction applications.

- description

- Details

-

-

1.Data

Data JT1150 GT1150 Appearance Light yellow or yellow transparent viscous liquid Light yellow or yellow transparent viscous liquid Solid content(%) 50±2 60±2 Viscosity(cps/25℃) 1000±500 15-90 Smell No smell No smell Mixing ratio 20 2.5-3.5 2.Recommended technology

- Suitable for dry laminating machines of various speeds

- The recommended ratio of 20:3 is the conventional ratio. The actual environmental humidity and printing ink have a significant impact on the composite effect. Customers should adjust the amount of curing agent appropriately according to the actual situation.

- When diluting, add the solvent to the main agent according to the required solid content, stir thoroughly, then add the curing agent, and stir evenly before use. Note: The water content of ethyl acetate shall not exceed 0.03%, and the alcohol content shall not exceed 0.02%. When the solvent contains active hydrogen (such as alcohol, amine), side reactions will occur, resulting in a decrease in the effective content of the curing agent. In actual use, the mixing ratio should be adjusted appropriately according to the situation.

- In order to evaporate the solvent in the adhesive layer of the substrate film, the drying efficiency of the drying machine should be improved as much as possible.

3.Amount of adhesive &Curing

- The recommended coating amount is ≥2.0g/㎡ (dry basis). In actual application, customers can increase the coating amount appropriately according to the situation.

- The composite product should be cured in a curing room at (50±5)℃ for at least 48 hours.

4.Storage & Safety

- In a dry, clean, cool environment at 5-30℃, unopened JT1150/GT1150 can be stored for 12 months.

- After contact with adhesive, it should be thoroughly cleaned, including work clothes, protective glasses, masks and gloves stained with adhesive.

- Be careful! Empty drums of adhesive after use also contain hazardous substances. Please handle according to the instructions on the label and do not use these empty drums without professional cleaning.

- If you need more safety information, please refer to our product safety data sheet.

5.Packing data

- JT1150:20KG/Drum OR 200KG/Drum

- GT1150:4KG/Drum OR 20KG/Drum

Product Categories

hot products